2025 Electronic Components Market: Opportunities and Challenges under the Wave of Technology

At a time when technology is developing rapidly, electronic components, as the basic building blocks of modern electronic devices, are undergoing profound changes in the market. In recent years, the scale of the global electronic components market has continued to show a steady expansion trend. Relevant data show that global semiconductor sales will reach approximately US$626.87 billion in 2024, a year-on-year increase of 19%. This data marks that the global semiconductor market has officially bid farewell to the downward cycle and firmly entered the recovery track. Entering 2025, this growth trend will continue thanks to the continuous breakthroughs in technological innovation, the continuous growth of market demand and the strong promotion of policy support.

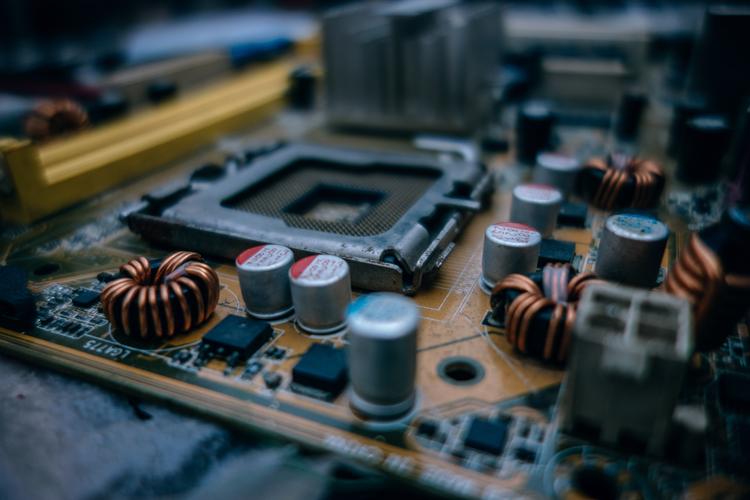

Main product classification and application

Electronic components are rich and varied. From a functional perspective, they can be divided into semiconductor devices, passive electronic components (such as capacitors and resistors), connectors, etc. Among them, integrated circuits (ICs), as the key representative of semiconductor devices, are widely used in many fields such as computers, communications, and consumer electronics, and can be regarded as a key factor in promoting the development of the industry. Take the computer central processing unit (CPU) as an example. It integrates hundreds of millions of transistors and can quickly process massive amounts of data, which determines the speed and performance of the computer. In the field of communications, the radio frequency chip in the 5G base station is also an important application of integrated circuits. It is responsible for the transmission and reception of signals, ensuring the high-speed and stable communication of the 5G network.

With the rapid development of emerging technologies such as 5G, the Internet of Things (IoT), and artificial intelligence (AI), new electronic components, such as smart sensors and power semiconductors, are gradually becoming the focus of the market. Smart sensors can sense various physical quantities such as temperature, humidity, pressure, and light, and convert them into electrical signals for output. They are widely used in smart homes, smart cars, industrial automation and other fields. In smart home systems, temperature and humidity sensors can monitor indoor environmental parameters in real time, automatically adjust the operation of equipment such as air conditioners and humidifiers, and create a comfortable living environment for users.

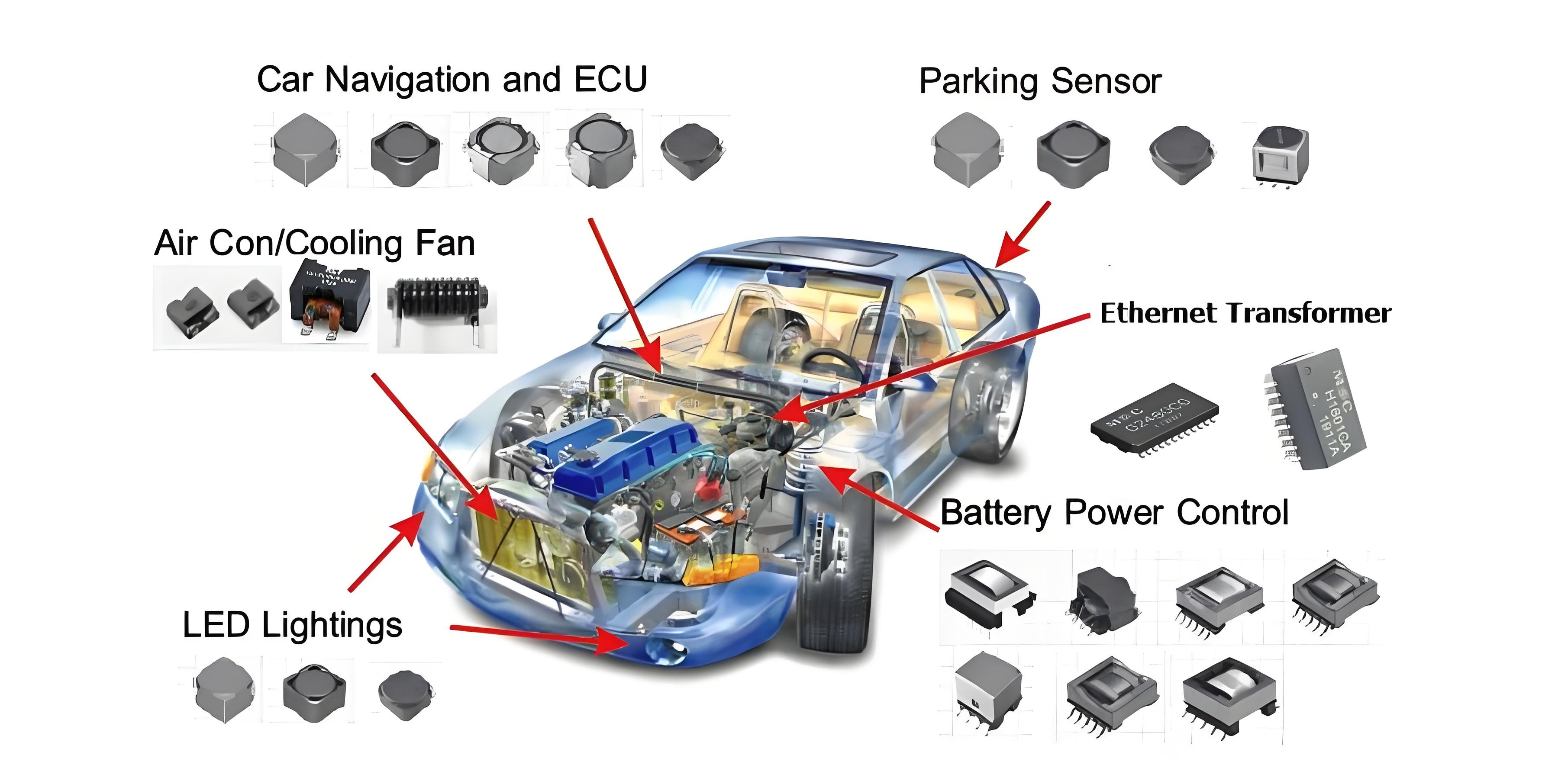

Power semiconductor devices, such as insulated gate bipolar transistors (IGBTs) and metal oxide semiconductor field effect transistors (MOSFETs), play a vital role in industrial automation, new energy, and electric vehicles. In the field of industrial automation, IGBT modules are often used in motor drive systems, which can accurately control the speed and torque of the motor, improve production efficiency and the stability of equipment operation. In new energy vehicles, IGBT is responsible for converting the direct current of the battery into alternating current to drive the motor. It is one of the core components of the power system of new energy vehicles, and its performance directly affects the vehicle's cruising range, power performance and charging speed.

Industry Chain Distribution and Competition Pattern

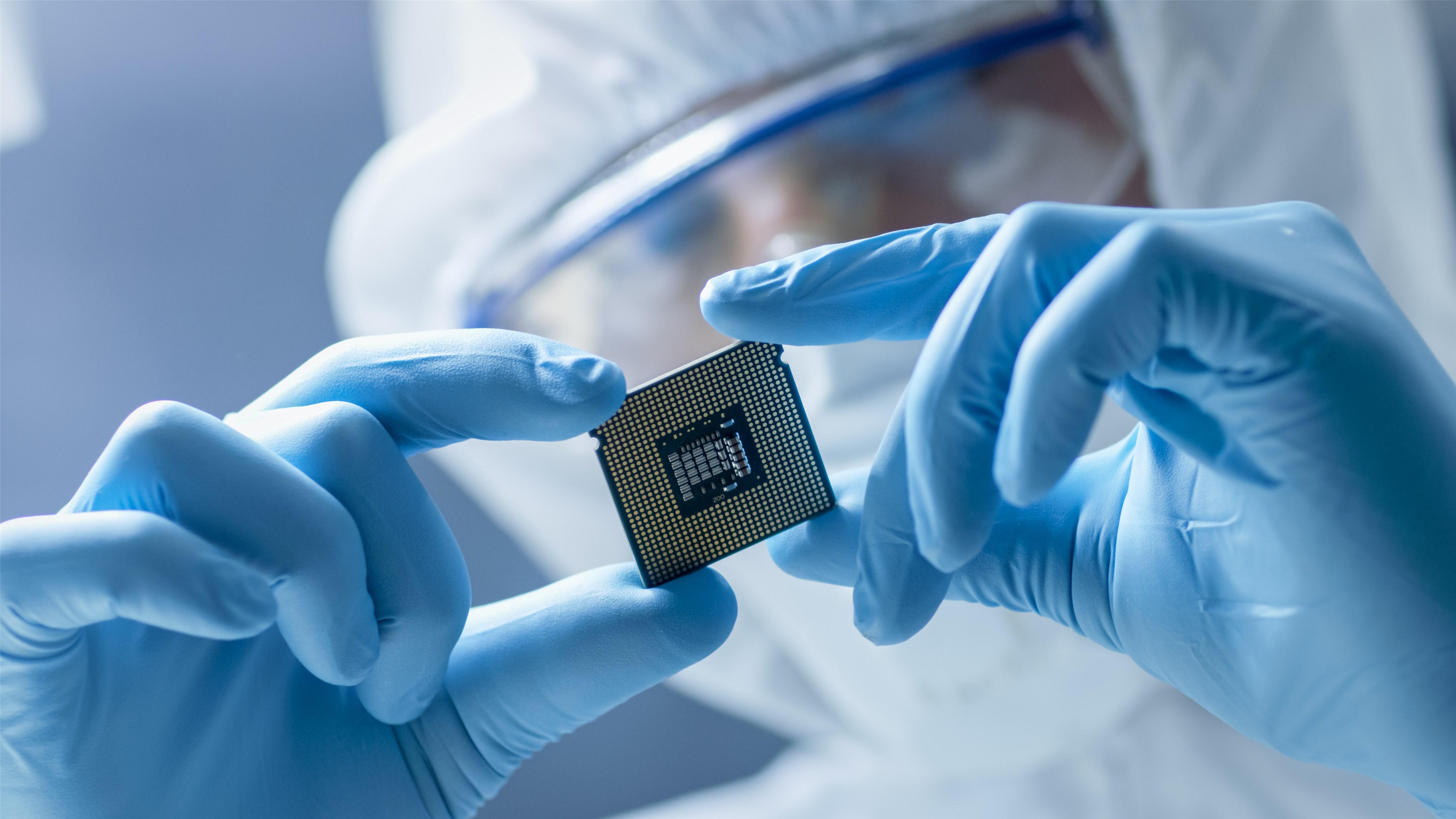

The electronic component industry chain covers multiple links such as design, manufacturing, packaging and testing, presenting a highly specialized division of labor model. Globally, the Asia-Pacific region, especially China, Japan and South Korea, has become the main gathering place for the global electronic component industry with strong market demand and a complete industrial chain system. As one of the world's largest producers of electronic components, China not only has a huge production scale, but is also constantly improving the layout of the industrial chain. From basic materials to high-end chip manufacturing, all links are gradually achieving technological breakthroughs and industrial upgrades.

The competition in the semiconductor industry is extremely fierce. International giants such as TSMC, Samsung, and Intel have launched an all-round competition in technology research and development, market share, and brand building. As the world's largest foundry, TSMC has a leading position in high-end chip manufacturing with its advanced process technology, and provides chip foundry services for many well-known companies such as Apple and Huawei. Samsung has strong competitiveness in the market with its technological advantages in memory chips and semiconductor manufacturing. As a traditional chip giant, Intel has long dominated the processor field and has continuously invested in research and development to promote the improvement of chip performance.

At the same time, Chinese chip manufacturers face many challenges in their development. In recent years, due to factors such as intensified market competition and pressure for technological upgrades, the number of deregistration/bankruptcy of some Chinese chip manufacturers has increased. However, this has also created opportunities for industry integration and the arrival of a new cycle. Under the survival of the fittest in the market, some companies with technical strength and innovation capabilities have begun to emerge, and have gradually gained a foothold in the fiercely competitive market by strengthening R&D investment, improving technical level, and expanding market share. Like Huawei HiSilicon, it has achieved a major breakthrough in the field of 5G baseband chips. Its Kirin series chips have won wide recognition in the global market with their excellent performance and innovative technology, which has strongly promoted the development of China's chip industry.

Technological innovation and green environmental protection trends

Technological innovation is undoubtedly the core driving force for the sustainable development of the electronic components industry. In the current development process, as Moore's Law gradually approaches its physical limit, the industry has begun to actively explore new materials, innovative processes and cutting-edge technologies to seek breakthroughs and new development paths. The application of new semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) is becoming the focus of industry attention.

These new semiconductor materials have excellent performance advantages. They have higher breakdown voltages, which enables electronic components to operate stably under high voltage environments, greatly improving the safety and reliability of equipment; at the same time, their lower on-resistance can effectively reduce energy loss and significantly improve the efficiency of power electronic systems. Taking new energy vehicles as an example, charging piles using silicon carbide power modules can achieve faster charging speeds and higher energy conversion efficiency, providing strong support for the popularization and development of new energy vehicles. In 5G communication base stations, the application of gallium nitride RF devices can improve the transmission power and transmission efficiency of signals, and ensure high-speed and stable communication of 5G networks.

Green environmental protection has become a broad consensus in the global electronic components industry. With the continuous improvement of global environmental awareness, the electronic component industry has responded positively and began to pay great attention to the research and development and production of environmentally friendly products such as lead-free and low-energy consumption. Many companies have invested a lot of resources to develop environmentally friendly products such as lead-free solder and low-power chips. The application of lead-free solder effectively reduces the harm of harmful substances such as lead to the environment and human body during the production and use of electronic products. The research and development and application of low-power chips reduce the energy consumption of electronic equipment, which is in line with the concept of sustainable development.

This not only conforms to the trend of the times and the needs of industry development, but also lays a solid foundation for enterprises in future market competition. More and more consumers will give priority to environmentally friendly products when purchasing electronic products, which prompts companies to accelerate the research and development and production of green and environmentally friendly products. At the same time, governments of various countries have also introduced a series of environmental protection laws and policies, which have put forward higher requirements for the environmental protection standards of the electronic component industry and promoted the industry to develop in the direction of green environmental protection.

Emerging technologies drive market changes

The promotion of 5G and the Internet of Things

The commercial deployment of 5G technology and the widespread application of the Internet of Things have brought new growth points to the electronic component industry. 5G provides strong communication support for the development of the Internet of Things with its high speed, low latency and large capacity. The construction of 5G base stations and the popularization of IoT devices have driven the demand for high-performance electronic components, such as high-frequency, high-speed and low-power integrated circuits and sensors. It is estimated that by 2025, the number of 5G base stations worldwide will reach 10 million, which will greatly promote the market demand for 5G core electronic components such as RF devices and optical communication devices. In the field of IoT, the continuous expansion of application scenarios such as smart homes, smart wearables and smart factories has led to a continuous growth in the market demand for smart sensors. It is estimated that by 2025, the global smart sensor market will reach US$200 billion, with a compound annual growth rate of 15%. The integration of 5G and the Internet of Things will also promote the development of smart cities, smart homes, smart factories and other fields, and further broaden the application scenarios of electronic components. In smart cities, a large number of sensors and communication equipment are used to realize intelligent management of various aspects such as urban transportation, energy and environment, which cannot be separated from the support of various high-performance electronic components.

The rise of new energy vehicles

The rapid development of new energy vehicles has had a significant impact on the electronic components industry. Electric vehicles have a growing demand for high-performance and high-efficiency electronic components, especially in battery management systems (BMS) and motor drives. The battery management system is responsible for monitoring the status of the battery, including voltage, current, temperature, etc., and ensures the safe and stable operation of the battery and extends the battery life through precise control and management. This requires electronic components such as high-precision sensors and high-performance microcontrollers. The motor drive system requires power semiconductor devices such as insulated gate bipolar transistors (IGBTs) and metal oxide semiconductor field effect transistors (MOSFETs) to achieve efficient control of the motor and provide strong power output. With the increase in the market share of hybrid vehicles and plug-in hybrid vehicles, the application of electronic components in these models will also be further expanded. The popularization of new energy vehicles will also drive the construction of infrastructure such as charging piles and battery swap stations, further promoting the development of the electronic components market. In charging piles, electronic components such as power semiconductors and magnetic components are needed to achieve efficient power conversion and a stable charging process.

The promotion of industrial automation

The promotion of industrial automation is one of the key drivers of the growth of the electronic components industry. With the rise of concepts such as smart manufacturing and Industry 4.0, the demand for high-efficiency and high-reliability electronic components in industrial production is increasing. In industrial automation production lines, a large number of electronic components such as sensors, controllers, and actuators are needed to realize the intelligence and automation of the production process. Sensors are used to monitor various parameters in the production process in real time, such as temperature, pressure, position, etc., and feed this information back to the controller. The controller analyzes and processes the data from the sensor according to the preset program and algorithm, and then issues instructions to control the action of the actuator to achieve precise control of the production equipment. Applications in the fields of motor drive, variable frequency speed regulation, power control, etc. have enabled electronic components to continue to expand their market share in the field of industrial automation. In industrial robots, a large number of electronic components such as servo motors, encoders, sensors, etc. are needed to achieve precise motion control and task execution of robots. In the future, with the in-depth development of industrial automation, the electronic component industry will usher in more growth opportunities. With the development of the industrial Internet, the interconnection between industrial equipment will be closer, and the demand for communication electronic components will also increase significantly.

Integration of artificial intelligence

The rapid development of artificial intelligence technology has promoted the transformation of the electronic components industry. In the future, artificial intelligence will continue to be integrated into a wider range of devices, driving the growth of demand for electronic components. Especially in the field of AI chips, with the continuous advancement of technologies such as deep learning and natural language processing, the demand for high-performance, low-power AI chips will continue to increase. AI chips are the core of artificial intelligence devices. They can quickly process large amounts of data, realize complex algorithm operations, and provide powerful computing power support for artificial intelligence applications. In addition to AI chips, the application of artificial intelligence will also drive the development of data centers, cloud computing and other fields, and further broaden the application scenarios of electronic components. In data centers, a large number of servers, storage devices, network devices, etc. are needed, and these devices are inseparable from the support of various electronic components. With the continuous expansion of the application of artificial intelligence in smart homes, smart security, smart medical care and other fields, higher requirements are put forward for the performance and reliability of electronic components, which also brings new development opportunities to the electronic components industry. In the intelligent security system, the surveillance video is analyzed and processed by artificial intelligence technology to realize real-time monitoring and early warning of abnormal behavior, which requires high-performance image sensors, processors and other electronic components to ensure the efficient operation of the system.

Green environmental protection and sustainable development

Against the backdrop of growing global environmental awareness, the electronic component industry is actively moving towards a green and low-carbon direction. This is not only an inevitable trend in the development of the industry, but also an important measure for enterprises to fulfill their social responsibilities and meet market demand.

From the perspective of material selection, the application of environmentally friendly materials is becoming more and more extensive. In the production of printed circuit boards (PCBs), the use of halogen-free materials significantly reduces the emission of harmful substances. This material does not contain halogen elements such as chlorine and bromine, avoids the production of toxic gases during combustion, and effectively reduces potential harm to the environment and human health. Bio-based materials are also beginning to emerge. They are derived from renewable resources such as corn starch and cellulose, reducing dependence on petroleum resources and reducing carbon footprint. Some companies use bio-based film materials in film capacitors, which improves the environmental performance of products while ensuring product performance.

The optimization of production processes is also a key link in green environmental protection. More and more electronic component manufacturers are adopting clean production technologies to reduce the generation of pollutants from the source. By improving production processes and adopting advanced equipment and processes, energy utilization efficiency is improved and the emission of wastewater, waste gas and waste residue is reduced. Some companies have optimized the photolithography process in the chip manufacturing process, reduced the use of chemical reagents, and improved the production accuracy and quality of chips.

The recycling and reuse of discarded electronic products are also highly valued. With the accelerated replacement of electronic products, the amount of electronic waste is increasing day by day. In order to meet this challenge, the industry has strengthened the construction of the recycling system and improved the recycling rate of electronic waste by establishing a complete recycling network. Advanced recycling technologies are constantly emerging, which can efficiently extract valuable metals, plastics and other materials from discarded electronic products to achieve resource recycling.

Many companies are also actively involved in electronic waste recycling and reuse projects, and cooperate with professional recycling companies to establish a complete industrial chain from recycling, disassembly to reuse. Through these efforts, not only the pollution of electronic waste to the environment is reduced, but also the demand for new resources is reduced, achieving a win-win situation of economic and environmental benefits. This series of green and environmental protection measures not only helps to promote the sustainable development of the electronic components industry, but also makes positive contributions to global environmental protection.

Industry chain integration and coordinated development

With the increasingly fierce market competition, the integration of the electronic components industry chain has become an important trend in the development of the industry. The cooperation between upstream and downstream of the industrial chain is constantly strengthening. Enterprises in various links have achieved complementary advantages and coordinated development through strategic cooperation and resource sharing. This integration not only helps to improve the overall competitiveness of the industry, but also enhances the industry's ability to resist risks.

In the semiconductor field, many companies have strengthened their collaboration in design, manufacturing, packaging and testing through mergers and acquisitions, strategic cooperation and other means. Intel's acquisition of Altera further strengthened its layout in the field of programmable logic devices and achieved the coordinated development of technology and market. TSMC maintains a close cooperative relationship with customers such as Apple and Huawei, jointly developing advanced process technologies, meeting customers' demand for high-performance chips, and also improving its own technical level and market share.

In the field of passive electronic components, companies have reduced costs and improved production efficiency through joint research and development and shared production facilities. Murata Manufacturing and TDK have cooperated in the field of multilayer ceramic capacitors to jointly develop new technologies and expand the market, consolidating their leading position in this field.

Industry chain integration also promotes the research and development and application of new technologies. By integrating resources from upstream and downstream of the industrial chain, companies can accelerate the pace of technological innovation and promote the research and development and commercialization of new products. In the field of IoT, suppliers of electronic components such as sensors, communication chips, and microcontrollers work closely with IoT device manufacturers to jointly develop IoT solutions that adapt to different application scenarios, promoting the widespread application of IoT technology.

In the future, the integration of the electronic component industry chain will be more in-depth, and collaborative development between enterprises will become the norm. By strengthening the integration and collaborative development of the industry chain, the electronic component industry will achieve greater breakthroughs in technological innovation, market expansion, and other aspects, and achieve sustainable development.

Summary and Outlook

Looking forward to 2025, the electronic components market will face both opportunities and challenges. The vigorous development of emerging technologies has brought broad growth space to the market. The rapid development of 5G, Internet of Things, new energy vehicles, industrial automation and artificial intelligence will continue to drive the growth of demand in the electronic components market.

Technological innovation will continue to be the core driving force for the development of the industry. The application of new materials, innovative processes and cutting-edge technologies will continue to promote the improvement of electronic components performance and the upgrading of products. The integration and coordinated development of the industrial chain will also become an important trend in the development of the industry. By strengthening cooperation between upstream and downstream of the industrial chain, achieving complementary advantages and collaborative innovation, it will help improve the overall competitiveness and risk resistance of the industry.

Green environmental protection and sustainable development have become an industry consensus, and the trend of the electronic components industry towards green and low-carbon development is irreversible. In the future development, the electronic components industry needs to keep up with technological trends, continue to innovate, strengthen the coordinated development of the industrial chain, and focus on green and low-carbon development to cope with the ever-changing market environment and competitive challenges. Only in this way can we be invincible in the fierce market competition and achieve sustainable development.